In the fast-evolving world of construction and demolition, innovation plays a crucial role in ensuring safety, efficiency, and precision. One such breakthrough is the BRH Robot de Démolition. This robot represents the next step in demolition technology, offering several advantages that conventional methods lack. As businesses look to improve productivity and minimize risks on job sites, robots like this are becoming indispensable tools.

In this article, we will take an in-depth look at the BRH Robot de Démolition, its applications, advantages, and how it can change the future of demolition projects.

What is the BRH Robot de Démolition?

The BRH Robot de Démolition is a state-of-the-art robotic system designed specifically for demolition tasks. Equipped with advanced hydraulic hammers, drills, and other attachments, it performs various functions, including breaking concrete, removing debris, and dismantling structures. Unlike manual labor, which exposes workers to safety risks and physical strain, this robot offers a safer and more efficient alternative.

Key Features of BRH Robot de Démolition

The BRH Robot de Démolition boasts several features that set it apart from traditional demolition equipment. These include:

- Remote-Controlled Operation

Operators can control the robot remotely, reducing the risk of injury from falling debris or unstable structures. This remote control feature allows for precision demolition in hazardous environments. - Compact and Flexible Design

The robot’s compact design makes it ideal for use in confined spaces. It can easily navigate through narrow hallways, doorways, and other restricted areas where larger machinery would struggle. - Powerful Performance

Equipped with high-powered tools such as hydraulic breakers, the BRH Robot de Démolition can break through even the most robust materials, including reinforced concrete, brick, and steel structures. - Energy Efficiency

Many models are powered by electricity or batteries, making them more environmentally friendly compared to traditional fuel-powered demolition equipment. - Customizable Attachments

The robot comes with a range of interchangeable attachments, such as hydraulic hammers, crushers, and shears, which make it versatile for different demolition tasks.

Applications of BRH Robot de Démolition

The BRH Robot de Démolition is versatile enough to be used in a variety of demolition projects. Some common applications include:

- Building Demolition

Robots are employed in demolishing large structures, including residential buildings, commercial properties, and industrial facilities. - Selective Demolition

When only certain parts of a building need to be removed, robots like this can perform highly accurate demolition, leaving intact the sections that need to remain undisturbed. - Underground and Confined Space Demolition

In underground mines, tunnels, and confined spaces, manual labor is both dangerous and inefficient. Robots offer a safer and more efficient solution in these environments. - Disaster Recovery

After earthquakes, fires, or other disasters, robots can be deployed to safely dismantle unstable structures or remove debris.

Benefits of Using the BRH Robot de Démolition

Enhanced Safety

One of the primary reasons for using demolition robots is the improvement in safety. BRH Robot de Démolition keeps human workers at a safe distance from dangerous demolition zones. This reduces the risk of accidents, injuries, and exposure to hazardous materials such as asbestos or dust.

Increased Efficiency

The robot’s advanced features, including remote operation and powerful hydralic tools, allow for faster and more efficient demolition work. With fewer disruptions, the project can be completed more quickly, reducing costs and downtime.

Precision Demolition

Manual demolition methods often result in unintended damage to surrounding structures. With the BRH Robot de Démolition, operators have full control over the robot’s actions, enabling them to perform highly precise demolition tasks. This is particularly valuable in projects that require selective demolition, where only certain parts of a building are removed.

Cost-Effectiveness

While the initial investment in robotic demolition equipment might be higher than traditional methods, the long-term benefits far outweigh the cost. Robots complete tasks more quickly, reducing labor costs, minimizing delays, and avoiding the need for costly repairs caused by accidental damage.

Environmental Impact

The BRH Robot de Démolition is also more environmentally friendly. By using electric or battery-powered robots, construction companies can reduce their carbon footprint, as well as minimize noise and dust pollution.

How BRH Robot de Démolition Works

The robot is equipped with various hydraulic tools that allow it to break apart structures. Its remote-controlled functionality gives operators full control over its movements. Let’s explore the key steps in how the robot operates:

- Preparation

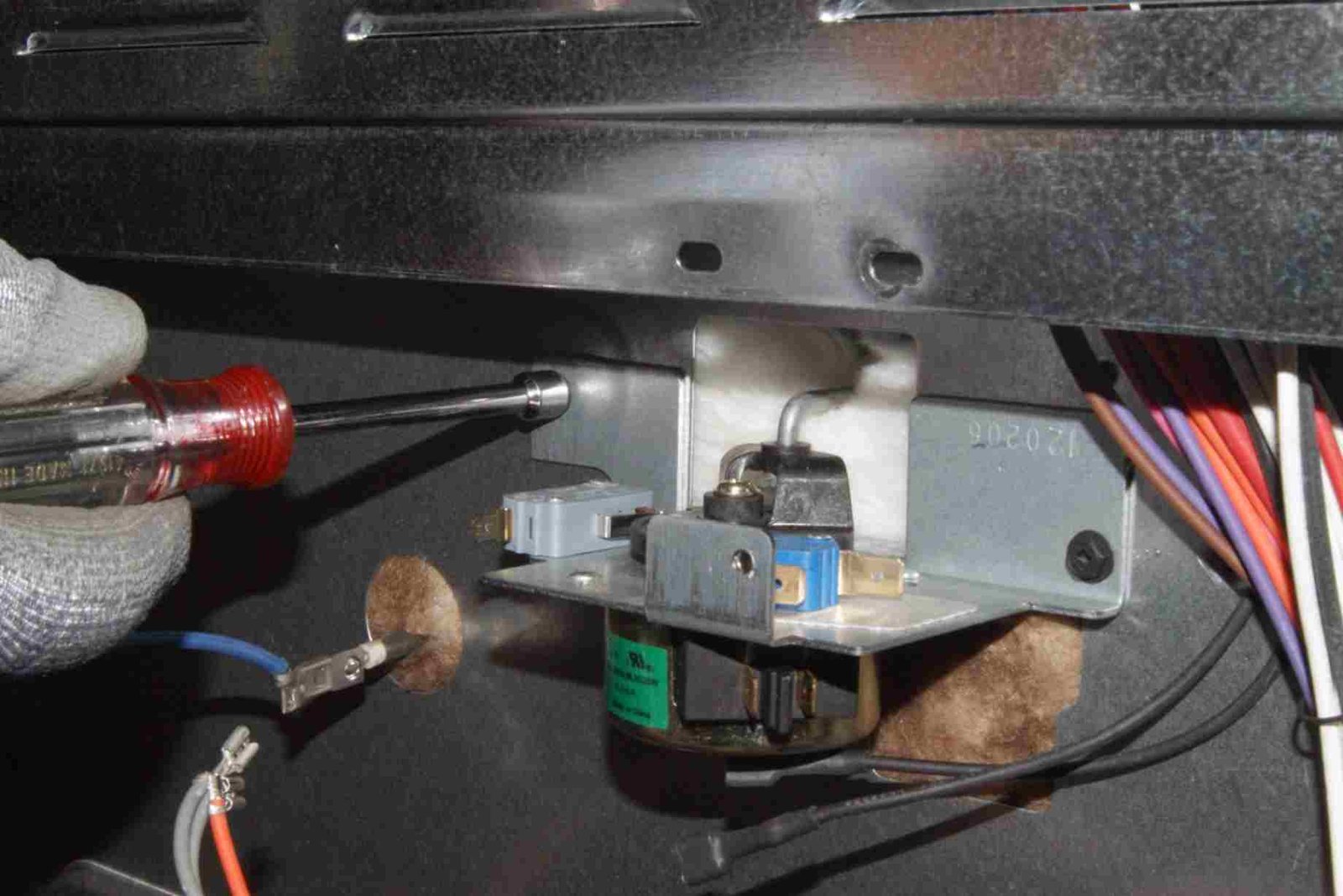

The demolition site is first assessed to determine where and how the robot will operate. This includes identifying any hazards, selecting appropriate attachments, and planning the demolition sequence. - Attachment Setup

Depending on the task, the operator selects the right attachment for the robot. For example, hydraulic hammers are ideal for breaking concrete, while shears can be used to cut through steel beams. - Remote Operation

Once the robot is in position, the operator controls it from a safe distance using a remote control system. The robot then performs the demolition, breaking apart the structure piece by piece. - Debris Removal

After the demolition is complete, the robot can be equipped with tools to clear the debris. This helps streamline the entire demolition process.

Table: Advantages of BRH Robot de Démolition vs Traditional Methods

| Feature | BRH Robot de Démolition | Traditional Methods |

|---|---|---|

| Safety | High | Low |

| Efficiency | High | Moderate |

| Precision | High | Low |

| Environmental Impact | Low | High |

| Cost-Effectiveness | High (long-term) | Moderate (short-term) |

| Adaptability to Confined Spaces | Excellent | Limited |

Choosing the Right BRH Robot de Démolition for Your Project

When choosing a BRH Robot de Démolition, it’s important to consider factors such as the size of the project, the type of materials that need to be demolished, and the working conditions. Smaller robots are ideal for confined spaces or selective demolition, while larger models are better suited for large-scale building demolition.

FAQs about BRH Robot de Démolition

Q1: What does BRH stand for in BRH Robot de Démolition?

BRH stands for “Broyeur Hydraulique,” which refers to the hydraulic breaker that is commonly used in demolition tasks.

Q2: Can the BRH Robot be used for outdoor demolition projects?

Yes, the BRH Robot de Démolition is versatile enough for both indoor and outdoor demolition work.

Q3: How much does a BRH Robot de Démolition cost?

The cost of a BRH Robot can vary depending on the model and its capabilities, but prices typically range from several thousand to tens of thousands of dollars.

Q4: What kind of maintenance is required for the BRH Robot de Démolition?

Regular maintenance includes checking the hydraulic system, replacing worn-out attachments, and ensuring the remote control system is functioning properly.

Q5: Are there any environmental benefits to using the BRH Robot de Démolition?

Yes, the robot’s electric or battery-powered options reduce carbon emissions, making it more environmentally friendly compared to fuel-powered equipment.

The BRH Robot de Démolition is transforming the demolition industry by offering unparalleled safety, efficiency, and precision. With its remote-controlled operation, energy-efficient performance, and ability to work in confined spaces, it has become a game-changer for construction companies worldwide. As technology continues to evolve, robots like the BRH will play an even more significant role in future demolition projects, helping to reduce costs, increase safety, and enhance environmental sustainability.